Unique Solar Harvesting System on display at the Pig & Poultry Fair 2024

DACS have developed the world’s first high-efficiency solar system to power their fans.

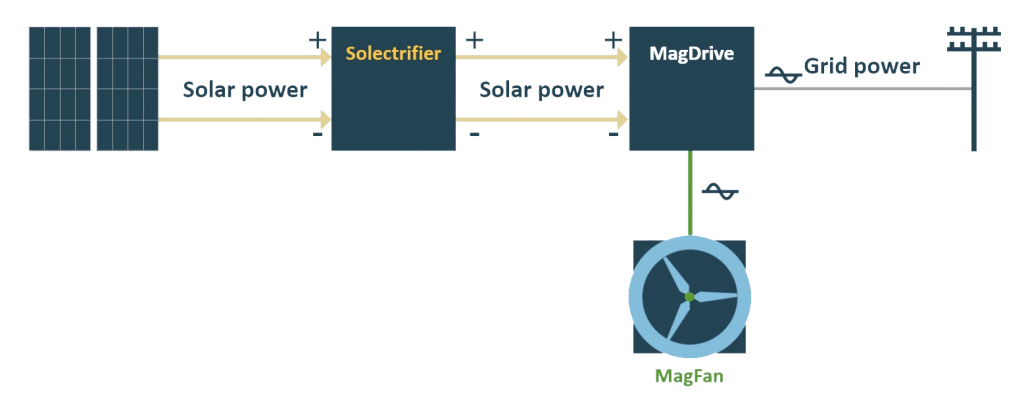

It is the world’s first Solar Power Harvesting System designed specifically as a fan Dual Power Supply unit. DACS call it the Solectrifier and claim that power reductions of up to 90% can be achieved with the system.

The Solectrifier is unique in the sense that it is not grid-tied and it is isolated from the public grid (AC-power). Since it does not connect to the grid it does not require special installation permits like most solar systems.

The Solectrifier is unique in the sense that it is not grid-tied and it is isolated from the public grid (AC-power). Since it does not connect to the grid it does not require special installation permits like most solar systems.

Moreover, it generates power for the fans completely independent from fired power, making it act like a backup and relief system, bringing down total system load during the often critical peak load hours.

The Solectrifier comes pre-programmed and connects to the DC-link in the DACS frequency drives with just two wires, plus and minus. The solar power production from PV panels is conditioned and controlled by the Solectrifier, the boosted to 400 VDC and fed into the DC link.

Depending on total power draw and solar intensity, the system then turns down the AC grid power input as much possible, whilst constantly maintaining the required energy flow in the DC link to match the fan’s power requirement. Any percentage mix from 100% solar power to 100% AC grid power is possible and the transition or blending from one power source to the other happens automatically, without any need for programming or human interaction.

The Solectrifier deals with sudden changes in solar power production or sudden changes in incoming AC voltage in a matter of milliseconds, creating a fast-response DPS (Dual Power Supply), which in essence is a backup if the public power grid disappears, but also a relief to the power-grid during high load periods.

High-Efficiency Solar Harvesting

Traditional PV inverter systems go through several conversion stages in the power handling and each stage results in efficiency losses. The current flow from the PV panels to the inverter is DC, which is then converted to AC and transported over relatively long distances at moderate voltage and high current to the point of consumption.

In the case of modern fan technology, the fans variable speed drive then typically converts the AC back to DC, only to turn it once again into AC, this time at a variable frequency.

Unlike traditional systems, the Solectifier operates at 400v DC and eliminates 67% of the conversion stages. This brings some distinct advantages compared to the traditional PV inverter systems;

- The Solectrifier system is not affected by grid failures as it operates behind the meter and distribution panels.

- As the system is not grid-tied, installation is much simpler and cheaper.

- With the Dual Power System, the entire ventilation system becomes more resilient and downtimes can be reduced, resulting in a higher level of welfare and production safety.

- With conversion and grid losses reduced by approximately 20% compared to conventional systems, the system ROI is more than on conventional PV inverter systems.

Daytime harvesting covers 90% of the fan’s power requirement

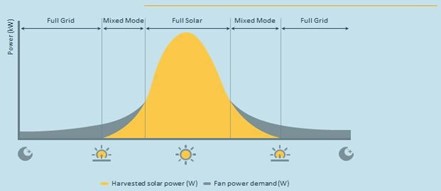

The Solectrifier system can be paired with battery storage, although usually, it does not pay to do so. Field studies have shown that, depending on location and control strategy, a properly sized Solectrifier system will provide up to 90% of the fan’s total power requirement.

The savings related to the fact that the consumption profile and the production profile match each other unusually well in a fan application, fans spinning faster and working harder during the daytime to create the required air exchange and then slowing down at night, with nighttime fan power consumption typically less than 30% of daytime peak consumption.

BPS Equipment will be showcasing DACS’ Solectrifier on stand 12-420 at the Pig & Poultry Fair 2024 on May 15th & 16th.